In the world of electronics, every component plays a crucial role. From the tiniest transistor to the mighty microprocessor, each one contributes to the symphony of functionality we rely on every day. But what happens when a wrong note enters the mix? Counterfeit electronic components, disguised as their genuine counterparts, can pose serious threats. From safety hazards and performance issues to project delays and financial losses, these fakes can wreak havoc on your work.

Identifying these imposters isn’t always easy, but we have 5 essential tips to help you spot counterfeit electronic components.

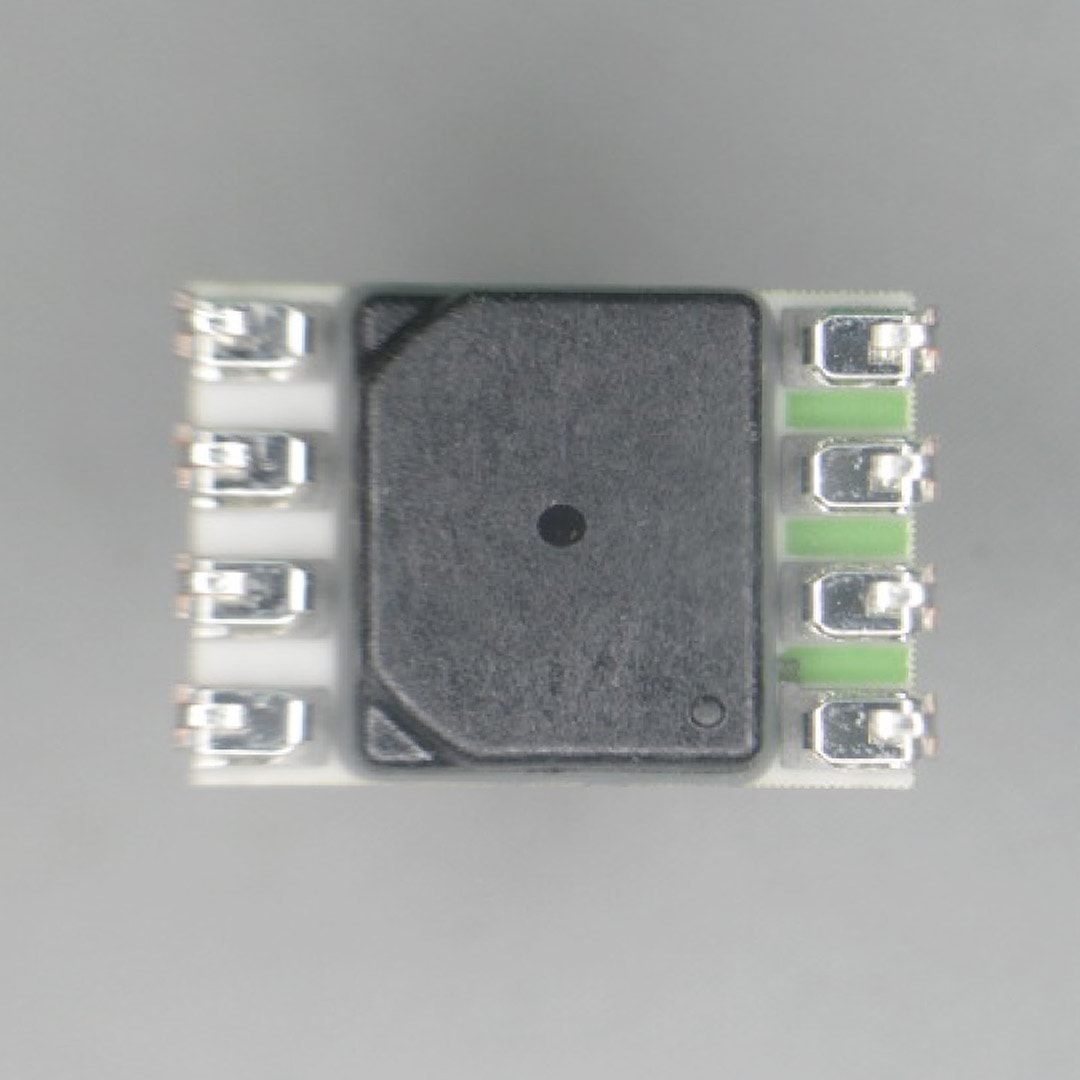

Physical imperfections matter as counterfeit components have imperfections that you can see and feel are wrong. Here’s what to look for:

- Physical defects: Uneven surfaces, chipped edges, or inconsistent lead spacing can be telltale signs of a counterfeit.

- Blacktopping: This is a common trick used to hide markings on recycled components. Be wary of parts with a suspicious black coating.

- Lead quality: Dull, tarnished, or unevenly plated leads are often a sign of poor quality and potential counterfeiting.

- Scratches and cracks: Legitimate parts undergo rigorous quality checks. Scratches and cracks signify carelessness or tampering.

- Inconsistent solder joints: Poor soldering skills leave behind uneven or dull joints. Look for shiny, consistent solder bonds.

A component’s markings are its identity card. Genuine parts will have clear, crisp markings with consistent fonts, spacing, and alignment. Look for inconsistencies like:

- Font and alignment: Are the letters uneven or misaligned? Do different parts of the same marking use different fonts?

- Typos and grammatical errors: Legitimate manufacturers wouldn’t mark a part with “resisto” instead of “resistor.” Check for spelling mistakes and awkward phrasing.

- Logo discrepancies: Does the logo look blurry or off-center? Are there extra lines or missing details?

- Date and lot code inconsistencies: Compare parts with the same date and lot code. Differences in font, size, or even the presence of the code itself can be a red flag.

Packaging can be another telltale sign. Genuine components typically come in high-quality, well-sealed packaging. Counterfeits, on the other hand, might show signs of:

- Grammatical errors or typos on labels and documentation.

- Low-quality printing or blurry graphics.

- Mismatched information between packaging and component markings.

- Unfamiliar or unverified distributors or manufacturers.

- Torn seals, re-glued boxes, or scratches that suggest someone might have messed with the packaging.

For critical applications or high-value projects, visual inspection might not be enough.

- X-ray inspection: Reveals internal anomalies like missing components or improper die size.

- Scanning acoustic microscopy (SAM): Detects hidden markings or modifications under coatings.

- Electrical testing:: Basic tests like measuring resistance or voltage can expose functional deficiencies and compare performance against manufacturer’s specifications.

Prevention is always the best strategy. Here’s how to avoid counterfeit components from the start:

- Buy from authorized distributors: Stick to reputable suppliers with established track records.

- Verify part numbers and datasheets: Cross-check information with the manufacturer’s website.

- Beware of unusually low prices: If it seems too good to be true, it probably is.

- Maintain traceability: Keep records of purchase and component information.